Veronica Constantin, vice president for global sustainability at Emerson, explains how advanced monitoring technologies and software are helping industrial manufacturers minimise their energy consumption and meet sustainability targets, while also detecting equipment failures.

The industrial sector accounts for 23% of total energy consumption. Up to 50% of a plant’s operating budget is typically spent on energy; therefore, minimising consumption through improved energy efficiency measures is vitally important. Emerson data shows companies can reduce their energy usage by up to 15% via energy management technologies and software that improve measurement, monitoring, targeting and reporting.

As companies evaluate their net zero roadmap, managing and lowering energy usage is low-hanging fruit that can deliver immediate results toward meeting vital sustainability goals.

Top Quartile performing organisations use 20% less energy than those in the bottom quartile. Implementing advanced digital technologies can help companies achieve Top Quartile energy management as they provide real-time visibility into energy performance, enabling operators to take corrective action.

Smart sensors, particularly wireless devices, have enabled better equipment monitoring and provide early detection of potential failures that could impact performance and increase energy use. Digital twin technologies also help optimise the design and operation of facilities, introducing new protocols to save energy without impacting plant performance.

One of the biggest recent advancements has been the use of energy management information systems (EMIS). Historically, plants have reviewed their energy consumption information monthly. However, an EMIS provides real-time data and analytics about a site’s energy consumption, quickly identifying inefficiencies and facilitating better decision making that can lead to millions of pounds being saved annually.

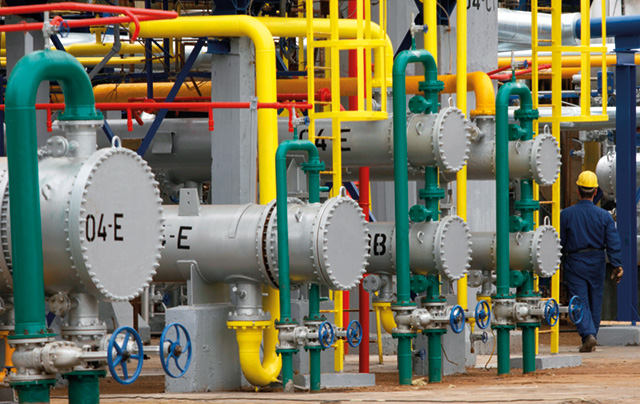

A good example is provided by Saudi Aramco’s Abqaiq plants, where Emerson’s EMIS was implemented to optimise operations and improve energy consumption management. The system provided increased visibility of operations performance, significantly reduced problem-to-resolution timelines, and resulted in annual energy savings of $22 million (£17.4 million).

While an EMIS facilitates site-wide energy usage reductions, there are also advanced measurement and monitoring applications that can help improve energy efficiency.

At most plants, steam heat provides the energy that drives operations. However, when companies are seeking ways to improve energy efficiency, they often overlook the thousands of steam traps that let condensed water out of steam systems. Steam trap failure is a common problem. Previously they were typically inspected manually once a year, but they can now be acoustically monitored with smart devices that alert operators to failures.

South African petrochemical company Sasol Technology installed acoustic monitors on 20 of its most critical steam traps and saved $42,000 (£33,250) in steam costs and $15,000 (£11,875) in maintenance costs annually.

Another area of opportunity for energy efficiency improvements is in the measurement of water, air, gas and steam. Flow meters help to detect leaks or unusual changes in energy usage, balance the flow of energy to use points and prioritise energy-saving actions.

Flow measurement technologies also help to improve energy efficiency in compressed air systems, which are major energy users and a main source of leaks. Precise control of steam boiler water levels is a further way to improve energy efficiency, with the goal to have stable boiler operation without costly cycles of shutdown, purge and restart.

Energy efficiency can also be impacted by issues with heat exchangers. Plants can often have hundreds of heat exchangers which can foul over time, thereby increasing maintenance costs and energy usage. Whereas heat exchangers were typically checked manually, advanced measurement technologies can now provide heat transfer, fouling and other degradation data to optimise heat exchanger performance.

At one of its refineries, Chevron partnered with Emerson and Microsoft to implement a predictive reliability and maintenance programme for heat exchangers, which has saved it millions of dollars per year in operational costs.

As these examples clearly illustrate, implementing software, data analytics and advanced monitoring technologies for real-time dynamic energy optimisation can result in swift and significant benefits, not only helping organisations to reduce their energy usage, but also in achieving their critical net zero targets.

www.emerson.com/uk/automation | uksales@emerson.com | t: 0870 240 1978