Industrial companies are unwittingly operating 30% blind due to critical gaps and errors in their technical documentation, according to ‘deeptech’ company Samp, developer of an AI-powered ‘Shared Reality’ solution for industrial sites.

Samp says that on average, industrial facilities modify around 2% of their assets every year, but only 50% of changes are properly recorded in their documentation. This leads to several issues including higher maintenance costs from outdated infrastructures, increased downtime due to inaccurate system maps, greater risks to safety and compliance standards, and an inability to properly upgrade and transform infrastructure.

Errors compound annually by 1%, so in a 30-year-old facility errors accumulate to 30%. Samp says with the average age of industrial facilities often exceeding this threshold, the true scale of the problem is often even greater.

This concern is said to echo a recent poll conducted among European industrial site managers highlighting widespread uncertainty over clean asset data. Of the 24 respondents, 14 provided insights on the percentage of clean technical asset data at their sites, with only one respondent claiming to have over 80% clean data, while a majority (12) estimated their clean data at 60% or below.

Samp CEO Laurent Bourgouin said : “We have always found between 20% and 30% errors or gaps in the technical documentation of industrial facilities. These findings reinforce the scale of the documentation challenge facing industrial sites, where poor data integrity contributes to inefficiencies and operational risks.”

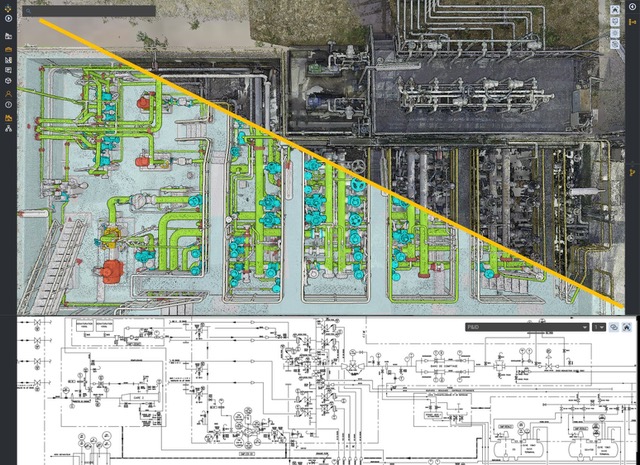

Bourgouin added: “Many sites don’t grasp that these issues can be addressed over a weekend, with Shared Reality capturing on-site data and offering teams a comprehensive view of their facilities. It integrates technical documentation with actual site conditions, providing teams with an interactive, collaborative workspace.

“This rapid deployment ensures that all stakeholders, from operators, maintenance, engineering to management can work with a single, reliable source of truth. Shared Reality empowers teams to execute work safely, efficiently, and with no surprises on site, ultimately closing the data gap that many sites struggle with. It is vital if industrial sites are to succeed in their digital transformation, save costs, and ensure safety.”