Faye Brophy, Head of Industrial at Axair Fans, explains the importance of selecting the right industrial fan for the task, both for performance reasons and cost. Opting for energy efficient EC fume extraction fans in a ventilation system can, for example, reduce energy consumption up to 20% without affecting performance.

Industrial, commercial or education sectors where there is a risk of exposure to dust, fumes or chemicals must ensure they can demonstrate compliance with HSE and COSHH legislation regarding the safe and efficient removal of hazardous substances.

Industrial and manufacturing processes and procedures can often produce hazardous and combustible airborne particles such as dust. This particulate must be extracted out of the working environment to protect other processes and any susceptible personnel. Industrial fans are one of the fundamental components utilised in local extract or multi-point ducted systems to remove these particles safely and efficiently.

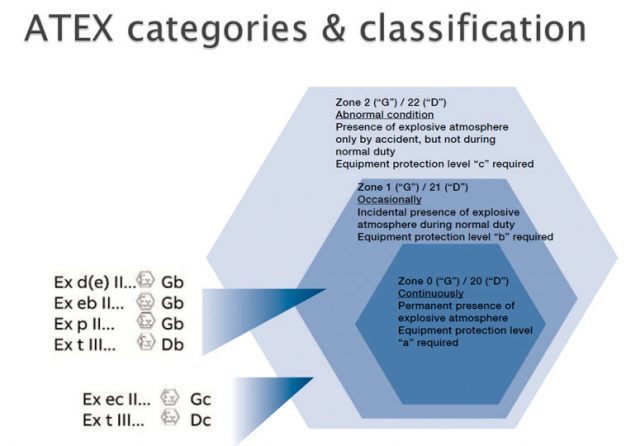

Material handling fans are required where dust, solid and bulky materials need to be handled or conveyed, for example in food processing or biomass applications. In food processing applications, the likes of flour, sugar and grain need to be transported during the production process to manufacture the final product, and where there are potentially combustible environments, an ATEX material handling fan suitable for the materials is required. The combustibility, the weight and the thickness of the individual fibres will dictate the type of ATEX or material handling fan most suitable for the application based on the ATEX category and classification.

ATEX is an acronym derived from the words “Atmospheres Explosibles” and forms part of a European equipment directive known as ATEX 2014-34 EU.

The directive covers manufacturing standards and ensures that people are protected against the risk that may be caused by dangerous substances. An application will require an explosion proof ATEX fan if there are flammable, combustible gases or dusts present at any time in the airstream.

An explosive atmosphere is defined as a mixture in atmospheric conditions caused by the activity of manipulating of the air and flammable substances (gas, vapour or dust).

These explosive atmospheres can occur in many industrial activities that surround us such as the chemical industry, power plants, landfills, food processing factories and metallurgical industries.

In the absence of large materials and dust, efficient fume exhaust systems have a preventative role in removing chemical mist, gas, vapour and fumes out of the air, through a ducting system and out to atmosphere so that they can’t be inhaled by staff in the workspace. A failing fan in a system will not sufficiently remove the harmful compounds and as such is an area that maintenance staff perform weekly checks on to ensure their smooth and safe operation.

Selecting the correct industrial fan in any environment where there is a risk of exposure to dust, fumes or chemicals is crucial to a safe and efficient operating system. The type of environment and size of a project will determine the number of fans required in a system to ensure maximum efficiency.

Polypropylene fume extraction fans are often the preferred choice in these types of environments due them being corrosion resistant and able to withstand harsh chemicals and fumes over a long-life span. It is vital that the fans in situ are well maintained and replaced where necessary to ensure the fume extraction system is working to full capacity.

Yet still Health & safety reports show that there are instances of insufficient ventilation and lack of safety measures to protect staff from long term health complications. Many companies have no exhaust ventilation in place at all and deem it unnecessary.

As energy prices continues to rise businesses look at ways to reduce costs and reduce energy consumption. Business owners are constantly being urged to consider the overall energy efficiency of their premises and their contribution to the overall UK energy consumption.

Many business leaders are looking to implement more energy efficient ventilation systems or upgrade their existing systems as a way of cutting costs and staying ahead of new UK energy targets. Opting for energy efficient EC fume extraction fans in a ventilation system can reduce energy consumption up to 20% without affecting the performance.

www.axair-fans.co.uk | sales@axair-fans.co.uk | t: 01782 349 430