Switching out cylindrical for sealed spherical roller bearings on a continuous casting machine at a major steelmaking plant in Europe doubled maintenance intervals, helping to significantly reduce downtime and maintenance costs.

Bearings specialist NSK was asked by the plant to help remedy a situation in which cylindrical roller bearings mounted to the casting machine were only lasting one to two months prior to failure.

The machine in question produces I-section beams using a series of rolls to maintain pressure on the profile as the molten steel solidifies; shaft mounted bearings support each set of rolls.

The cylindrical bearings were lubricated with oil via a complex system of piping, however high maintenance costs were the norm because of the time required to disconnect and reconnect these pipes after every bearing failure.

The service life of the bearings was so short due to the demanding nature of the application – involving high temperatures, contamination and high loading – as well as the design constraints of the machine which prevented the fitting of heavier duty bearings.

To provide an improvement, NSK proposed to fit the rolls of one segment of the machine with sealed spherical roller bearings, amounting to 60 in total.

The firm’s solution doubled the maintenance intervals to between two and four months due to the high sealing performance of the spherical bearings, resulting in substantial downtime and maintenance cost savings estimated at €14,850.

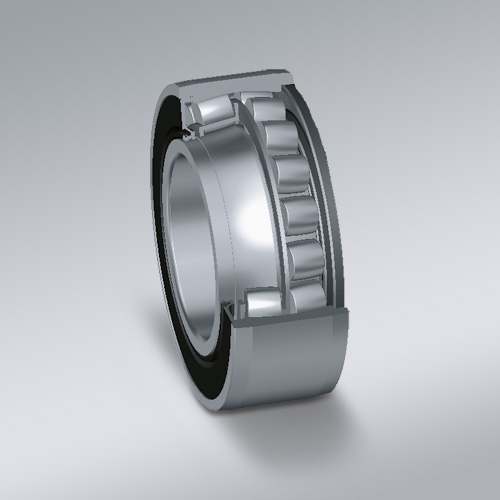

Instead of the single lip concept of standard sealed spherical bearings, NSK’s design uses outward extending, spring loaded lip seals made from nitrile rubber, which promises robust protection against the ingress of contamination.

NSK’s product also uses long life, temperature resistant grease, which eliminates oil costs. The grease does not require reapplication for the operating lifetime of the sealed NSK bearing, which means that dismantling and re-installing the oil piping system is no longer required after a bearing failure. Overall, this means the time required for the replacement of a segment is now claimed to be 10 hours, instead of 20 previously.

In terms of bearing design, the sealed spherical roller bearings feature symmetrical rollers and raceways to prevent edge loading problems at the contact points under high load operating conditions. In addition, a special chamfer configuration ensures smooth axial movement of the bearing at the free end.

Following the success of the project, NSK says the steelmaker has placed an order for 900 bearings with the intention of replacing the existing cylindrical roller bearings on all segments of the continuous casting machine.