Capabilities in automated inspection systems for composites are set to undergo a step change at the National Composites Centre (NCC) in Bristol following an investment of £1.4m.

A new Composite Integrity and Verification Cell (CIVC), due to be installed at the centre this autumn, will make inspection faster and more accurate. The system – to be designed and built by Ultrasonic Sciences– will initially deploy modern ultrasonic testing technology to quickly assess a wide range of composite structures, in a fast, repeatable and non-invasive way.

The aim is that further capabilities will be introduced over time, including thermography and shearography capabilities. These data layers would ultimately be combined to create a 3D model of the scanned component.

The NCC’s goal to incorporate multiple non-destructive testing methods in one inspection cell is expected to enable customers from different industry sectors to test and validate the integrity of a vast range of composite parts.

“The unique ability of the NCC’s inspection cell to build up detailed scans of a component, overlaying multiple capabilities to validate integrity, marks a significant step forward in our ability to deliver Industry 4.0 technology and techniques,” said NCC advanced technology programme manager Phil Slack. “The CIVC will help build trust and confidence in UK composites and we will be able to support a range of industries.”

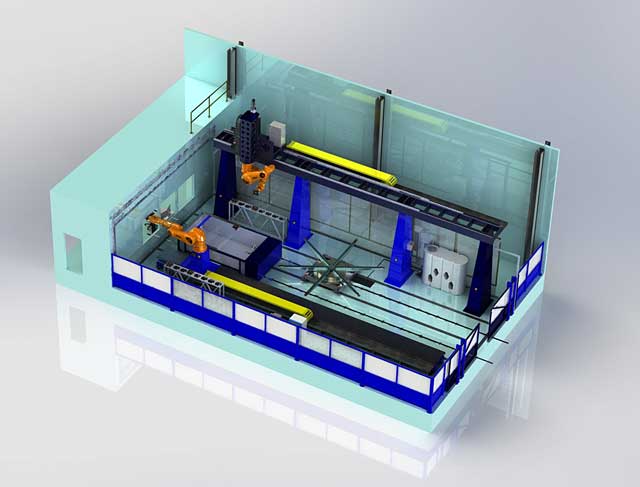

The CIVC works by building up a map of the quality of a composite throughout a component using ultrasonic scanning. The detailed mapping is made possible by two robot arms, one mounted on a rail about 4m high and one mounted at floor level.

Working together, the arms pass ultrasound waves via two jet streams of water, pointing directly at each other from either side of the component. The jets carry the sound from the robot to the surface of the component, and the system then listens for defects.

Ultrasonic Sciences sales manager Paul Hillman said: “The system will offer the latest capabilities in automated ultrasonic testing and will come equipped with an array of tools and techniques to suit a wide range of components.

“With the future addition to the machine of complementary technologies, the NCC will have a uniquely capable inspection platform with which to support industry challenges and lead the way in ‘inspection 4.0’.”

The new robotic inspection cell forms part of the NCC’s £36.7m iCAP Programme.