Latest developments in steam trapping technology are changing the view that high maintenance costs and extended downtime are inevitable, says Sam Mawby, technical director of Thermal Energy International.

Latest developments in steam trapping technology are changing the view that high maintenance costs and extended downtime are inevitable, says Sam Mawby, technical director of Thermal Energy International.

Steam as a heat transfer medium is essential to countless modern commercial and industrial applications. From food and beverage manufacturing through to petrochemical refining, the demand and uses for steam span many sectors, both private and public.

Although steam remains one of the most effective ways of transporting large quantities of heat energy around a plant, engineers, operators and maintenance professionals are under increasing pressure to improve efficiency and find cost savings.

In an unoptimised steam system, just 55% of fuel input results in useful heat output. Of the 45% waste, around 7% occurs as a result of pipe leaks and blowdown or standing losses. A further 10% is due to pipework insulation and condensate or flash losses. While some waste is unavoidable, up to 30% of all fuel input into a system is lost in steam traps and boiler stacks – the majority of which is preventable.

Waste not, want not

Waste not, want not

Good-practice steam trapping is vital for the efficient and safe running of a system. It prevents water hammer, which can seriously damage pipework, and guarantees processes achieve the temperatures required.

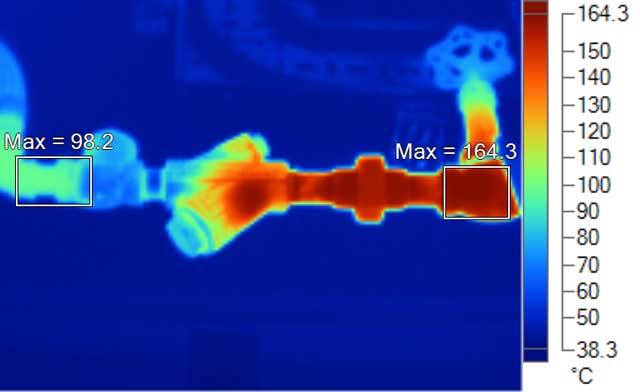

The function of any steam trap is to discharge air and condensate as they form, while limiting the loss of live steam. Traditional mechanical steam traps discharge condensate by opening and closing through various means, losing a little live steam with every cycle. In such an aggressive environment, moving parts are subject to failure, breakdown or wear and tear. The industry generally accepts a mechanical steam trap average failure rate of 5-10% annually. If they fail open, mechanical steam traps waste valuable energy. If they seize closed, there is a risk condensate will back up, causing problems for the whole system, as well as health and safety implications.

In many instances, it is more cost and time effective for maintenance engineers to replace a damaged mechanical steam trap than remove, repair and re-install it. This means steam traps are often seen as consumable items, rather than an opportunity for savings. Such an approach results in waste across the board, including fuel input, unnecessary downtime and increased maintenance costs.

Engineering a permanent solution

The simplest solution is to limit the level of steam trap failure. An increasing number of businesses are turning to a new generation of steam trap technology to permanently solve the problem. Innovative products, such as the GEM Trap, can exceed the performance of mechanical traps with the added benefit of having no moving parts to break or fail.

Such venturi orifice traps, as they are known, use an orifice and multi-staged throat design to manage condensate flow rate. The orifice is sized so that it is always protected by a seal of condensate. This allows the remaining condensate to be discharged continuously as it is created. As hot condensate flows through the orifice it moves from high pressure to the lower pressure throat. The sudden drop in pressure causes a known percentage of the condensate to re-evaporate as flash steam.

Restricting the re-expansion of the flash steam creates a localised variable back pressure in the throat. This is essential to accommodate the variations in industrial loads and is achieved without the need for moving parts. The combination of orifice and multi-stage throat differentiates venturi orifice traps from standard orifice traps, which cannot accommodate variable loads, making them unsuitable for most applications.

With fewer elements to service, such new generation steam traps reduce the maintenance burden on operators and engineers. It removes the cost of having to replace failed mechanical traps. Finally, for the wider business, it increases overall efficiency and reduces carbon dioxide emissions.

Moving away from traditional steam trapping methods and embracing developments, such as GEM, is proving a popular solution. An efficient steam system can make all the difference to both your carbon footprint and bottom line.