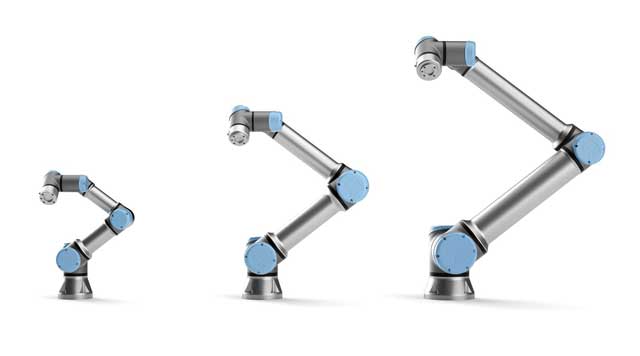

Cobot pioneer Universal Robots launched its next generation cobot range at last month’s Automatica 2018 show.

The flagship e-Series includes technology advances that allow faster development for a wider variety of applications, make programming easier, and meet the latest ISO safety standards.

A range of improvements include the built-in Force/Torque sensor to provide superior precision and greater sensitivity, allowing the e-Series to be used in a wider range of applications.

A redesigned touch-responsive interface (called the Teach Pendant) simplifies programming and reduces it to a few clicks on a new wide screen.

Universal Robots says it takes just an hour to unpack the cobot, mount it and program the first task. A wrist-joint/tool communication interface reduces integration time on the production line. For ease of maintenance, all joints can be replaced in 2-6 minutes.

17 safety functions include customisable stopping time and distance, and are certified by TÜV Nord to be in compliance with the EN ISO 13849-1 and EN ISO 10218-1 (Cat. 3 PLd) machinery safety standards for unobstructed human-robot collaboration.

Universal Robots president Jürgen von Hollen said the e-Series adopted the company’s overall product philosophy of “empowering, keeping it easy and making it accessible”, adding “the technology behind e-Series will give users much more operational ease and flexibility, and give them greater production output.”

Universal Robots is taking orders for the e-Series immediately and plans to begin shipping units to customers from the beginning of August.