ABSTRACT

Large fans of centrifugal or axial flow type are key items of auxiliary plant in fossil-fired power stations and in mining, process plant and other industries for moving gas and for ventilation. Experiences are described where condition monitoring of such fans was, and was not, successful.

INTRODUCTION

Fans are key machines in fossil-fired power stations, and have become used in very large sizes. The main applications are -:

- Forced Draft (FD): to supply air for combustion, with operating temperature between ambient and perhaps 60°C if air heater recirculation is used.

- Induced Draft (ID): to remove the products of combustion from the boiler to the stack, with operating temperatures up to 230°C.

- Primary Air (PA): to convey pulverised fuel and primary air through the milling system into the boiler, with operating temperatures up to about 150°C.

- Mill Exhauster: used in boilers burning high moisture lignites to extract hot gases from furnace exit level to mix with, and pulverise, the fuel and convey the product to the boiler’s burners.

Centrifugal types were usual, and are still applied where noise levels are of concern. Axial flow designs, however, have become popular. Fans are usually of steel construction mounted on concrete foundations. Given their relatively low speeds, usually between 590 rpm and 900 rpm, high reliability would be expected, and basic vibration monitoring could be expected to detect and monitor the major degradation modes.

Much of the experiences encountered with large fans can be applied to other simple machines consisting of a fan and its driver.

LOOSENESS OF FOUNDATIONS

With fans located and supported on concrete foundations, looseness can develop between the steel structure and the foundation. Vibration from unbalance due to deposition on blades can cause the anchor bolts to work loose. Retightening may be the cure, but sometimes an improved design is required.

With high vibration, the relative movement between steelwork and concrete may not be readily seen, nor detected by feel. Fortunately, a simple hand-held instrument works, taking measurements in either horizontal or vertical directions. Such a check should be done as a first step when excessive vibration occurs on such machines.

On a low speed double-entry fan, bearing horizontal vibration of 140 µm peak to peak was detected on routine monitoring, and was considered excessive [Beebe, 2001]. Horizontal measurements down the bearing pedestal metal and concrete parts showed vibration of 80µm on the steelwork, whereas it was only 45µm on the adjacent concrete.

Tightening of the bolts brought the vibration levels together and bearing vibration was then repeatable and acceptable.

An amusing part of this job was that the maintenance staff had been asked to check the bolts. However, they chose the bolts part way down the steel bearing structure rather than those into the concrete, which were beneath a grid floor and covered in coal dust and oil absorbent. A lesson in clear communication was also given that day!

CRACKING AND FAILURE OF FAN BLADES ON AN AXIAL FLOW FAN

A constant speed ID fan, single-stage axial flow, with control of output by variable inlet vanes, had presumably been scaled up from previously successful smaller models. Its free-standing blades were welded to the hub but, early in service, cracks would develop at the blade roots. Eventually, a blade would fail.

Routine monitoring of vibration overall level was being carried out, and was extended into frequency analysis every two weeks. At that time, more frequent measurements were not possible, as the available equipment had to be used elsewhere. Despite this attention, it was disconcerting that little change was detectable in the vibration data, and blades continued to fail.

Eventually, a full investigation involving strain gauging and stress analysis was performed by specialist engineers. This indicated that the time from inception of a crack to blade failure was about 48 hours. It was hardly surprising that the routine vibration analysis proved useless, given how infrequently analysis was performed compared to the mean time to failure!

The fan impeller was re-designed to add a continuous shroud ring connecting the blade tips. This reduced the efficiency of the fan a little, but the vibration-induced failures were eliminated.

EXTENSION OF FAN BLADES TO IMPROVE OUTPUT BY UTILISING MOTOR CAPACITY, AND FIELD TEST

Ash fouling of convection tube banks occurs in coal-fired boilers. Each of a series of eight boilers was fitted with two ID fans with output controlled by variable inlet vanes. As tube fouling progressed from the clean state, system resistance increased, so the control system opened the vanes more fully until maximum fan output was reached. Unit output then became limited towards the end of the service run. This meant that boiler cleaning outages were more frequent than desired.

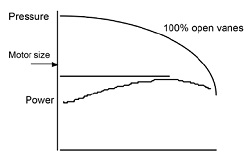

Higher fan performance would obviously have helped to extend service runs. It was noticed that these double-entry centrifugal fans, having the usual backward-curved blades, had a ‘non-overloading’ power-flow curve. This meant that the power drawn by the fan at operating conditions reached a maximum with increasing flow, then decreased at flows higher than this. The form of the curves is sketched in Figure 1. This maximum power was 1640kW, giving a margin of 140kW to the motor rating of 1780kW.

There was considerable activity at the same time in developing condition monitoring of pumps using performance analysis. It was noted from pump texts that pump impellers can be machined on the blades to reduce the diameter to better match duty conditions [Stepanoff, 1957]. As centrifugal fans follow exactly the same rotodynamic laws as pumps, a change in the diameter was proposed, but an increase rather than a reduction.

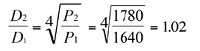

An increase in diameter by welding extensions on the blade tips was considered feasible. As the blade exit angle and gas path width would not change, the maximum allowable diameter to take advantage of the available motor power was calculated from the expression

This 2% increase in diameter corresponded to an extension of 32mm. The blade extensions were welded on carefully so that the blade exit angle was unchanged and balancing was not needed. The pressure and flow increased by 4%, which gave a useful performance boost. The fan was large, with no facility to measure the flow, so testing to confirm that the increase was achieved was performed by measurement of the pressure alone. As the static pressure was essentially constant at up to about 15% design flow, the fan was run with isolating dampers cracked open. The expected increase was observed.

ON-LOAD CLEANING OF FAN TO REDUCE VIBRATION

Routine vibration monitoring of the fans described above gave an increasing vibration trend. After some experience, it was found that deposits of ash built up on the impeller blades. As these were unevenly distributed, balance was affected and vibration increased. A technique which was often effective in reducing vibration without taking the fan from service was to perform on-load cleaning using river sand.

A load of sand was placed near the fan, and a person arranged to shovel it into a portable hopper which was made up with an air ejector outlet.Each shovelful of sand would whisk its way into the fan inlet section, and scour the deposits from the blades. Under the working conditions at that time, another person was needed to measure the vibration during this activity, and direct the shovelling to cease when vibration had reduced to normal levels.

As this activity was done on overtime, it was easy to justify purchase of a vibration meter with an output which could be connected to an adjacent chart recorder. Only one person was now needed, given instructions to stop shovelling sand when the chart pen showed that vibration was below the given level.

If the vibration did not respond, then a field balance would be arranged. This required the fan to be off-line and cooled for access and balanced as described in a previous article.

RESONANCE OF STRUCTURE A

Several fans driven by a constant speed motor through a scoop-controlled fluid coupling showed high vibrations, all at a frequency of 23.3Hz, closely corresponding to motor rotation speed. Not all of the machines showed this behaviour.

The coupling outer casing could be readily balanced using single-plane on-speed techniques. Balance weights as washers could be inserted under the bolts which fastened the driving ‘spider’ plate to the coupling. Expedients to speed up the balancing process were to paint phase reference numbers around the coupling periphery, and modify the heavy coupling guard with a small door to enable phase readings to be taken using a stroboscope, and balance adjustments to be made without lifting off the coupling guard.

Following balancing of some couplings, the vibration would increase dramatically when the scoop control was wound in to drive the associated fan. The vibration would beat at a frequency corresponding to the slip frequency, with phase angle varying in like manner. Although the coupling manufacturer assured that the runner impellers in the couplings were all ‘perfectly balanced’ at the works, the beating vibration was not fully overcome until the couplings were dismantled and the impellers balanced more precisely in a balancing machine.

Structural modifications were attempted to stiffen the motor, and a dynamic absorber added, with limited success. The motors had water-cooled heat exchangers mounted on top, giving a significant mass poised above the motor. Motors were replaced with an air-cooled type, of much lower profile, and the severe vibrations did not occur.

RESONANCE OF STRUCTURE B

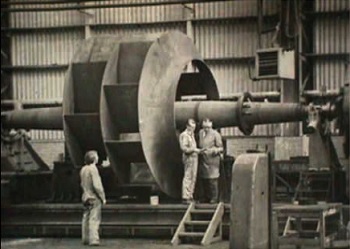

One of four 5MW ‘identical’ axial-flow fans had excessive vibration. Analysis showed that the dominant vibration was at rotation speed. Various measures were tried, including stiffening the 670 tonne structure with tie bolts from the bearings, and adding mass. Vibration was reduced slightly but eventually increased such that the fan failed. A thorough investigation included modal analysis and modelling, and led to the solution: substantial stiffening being added. Figure 3 shows the structure, as built and as modified (the motor weighs 24 tonnes ). It is not known why this fan was alone in exhibiting the behaviour.

REFERENCES

1. Beebe, R S Machine condition monitoring. MCM Consultants (Reprint 2001)

2. Stepanoff, A J Centrifugal and axial flow pumps. Wiley (1957)