ABSTRACT

In the face of a rapidly changing energy environment Nova Scotia Power Inc. (NSPI) has opted to adopt a comprehensive asset management approach across its fleet of generating stations. This approach, inspired by PAS-55 and the subsequent ISO55000 series of asset management standards, has an asset-centric focus. NSPI has been able to apply – to comparable asset classes across the fleet – common maintenance systems, identical planning practices, fleet wide reliability programmes, risk profiling and asset decision making. This has resulted in the most effective use of resources and investment dollars and therefore the lowest long term cost for customers.

INTRODUCTION

NSPI has had several business drivers for relinquishing their plant-centric approach to the management of their generating assets for a more holistic, asset-centric focus. Many of the company’s generators are over forty years of age, requiring maintenance strategies based on age related failure mechanisms. Senior staff with many years of experience have been retiring and have been replaced by capable, but inexperienced, staff. Increases in renewable energy sources have changed the utilization the traditional fleet (i.e. more cycling and two-shifting of steam units). And, more than ever, stakeholders and customers are expecting that the regulated company demonstrates ‘diligence and prudence’ in its operations.

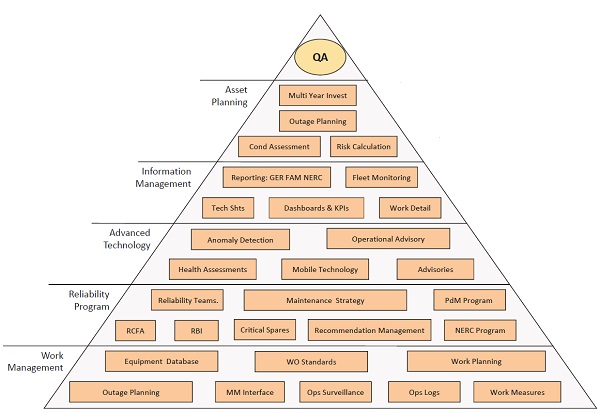

In short, the universal challenges of an aging infrastructure and workforce, along with industry specific and regulatory changes, have demanded a shift in the company’s organizational philosophy towards asset management. NSPI’s approach to this is illustrated in the Asset Management Pyramid shown in Figure 1 and the Asset Management Mechanism shown in Figure 2.

LAYERS OF ASSET MANAGEMENT

A key characteristic of Nova Scotia Power’s asset management approach is that it is ‘asset-centric’ as opposed to ‘plant-centric.’ This represents a significant organizational shift for the company. While there are dozens of aspects to asset management (as shown in Figure 1), Nova Scotia Power has deployed its approach in just five layers, as follows.

1) Work management. This is the foundational layer of the company’s asset management programme. All work management elements are standardized across the flee, including: work order formatting, coding, prioritization, information management, measures and scorecards. Standardization of the work management systems was extremely important in the company’s implementation of asset management, on two fronts:

- it demonstrated the ability to do things via a common approach across the fleet.

- it provided, from a change management perspective, the opportunity for senior management to demonstrate the resolve to apply common asset management programmes across the fleet.

In addition to maintenance work management, NSPI has deployed electronic operator rounds and electronic operator logs within an enterprise system. This enables the business to prescribe operational activities (rounds, inspections, tests) in support of holistic maintenance strategies that optimize Preventive Maintenance (PM), Predictive Maintenance (PdM), Operator Surveillance (Rounds, Testing) and Predictive Analytics (APR).. Furthermore, electronic logs now provide an easily accessible source of operator- initiated history in support of trouble shooting and equipment reporting. Operator functions are viewed as critical in the care of equipment and as a source of asset intelligence. For these reasons, key operator functions are well considered in the Work Management layer of NSPI’s asset management programme.

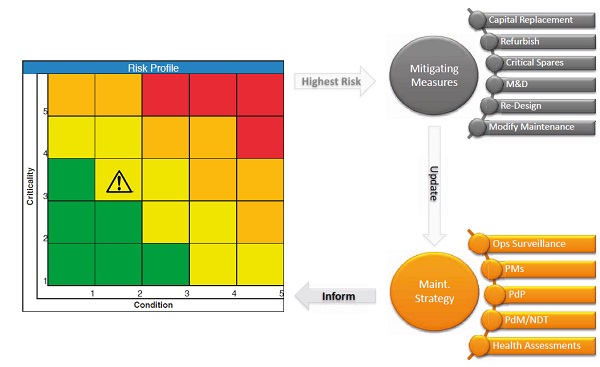

2) Reliability Programme. As the core reliability process, Maintenance Strategy focuses on the development and deployment of PM, PdM, Operator Surveillance and APR. The company’s reliability programme is asset-class based and leverages asset class reliability teams representing Plants, Engineering and Asset Management Specialists. This approach ensures that the most knowledgeable people in the business are focused on those asset classes that they understand best. The function of the reliability teams includes criticality rating, condition assessment, risk profiling, and risk mitigation, as well as modifications of maintenance strategies based on equipment performance and Root Cause Failure Analyses (RCFAs). The reliability process is illustrated in Figure 2’s ‘Asset Management Mechanism’ which illustrates how elements of the Asset Management Pyramid are integrated. The fleet reliability teams and reliability processes are viewed as key business advantages. Other reliability programmes include RCFA, Fleet PdM, Non-Destructive Testing (NDT), and Critical Spares and Recommendation Management.

3) Advanced technologies. Given the company’s changing demographics, NSPI has deployed leading technologies to support plant operations, reliability specialists, engineers and maintenance staff.

- Advanced Pattern Recognition (APR), delivers early indication of impending equipment issues as well as instantaneous alerts to specialist engineers and operations leaders.

- Real Time Performance Monitoring Systems, continually inform operators of performance degradation and provides detailed assessment tools for performance engineers.

- Mobile Technology, is utilized for operator rounds and testing as well as for maintenance and laboratory functions. Data is automatically integrated within fleet historians, asset health management system and scorecards

- Fleet Asset Health Indicators, are automatically updated from work management systems, PdM programmes and APR systems.

- Fleet Scorecards and Dashboards, are atomically updated from all work and asset management systems.

These technologies provide an enhanced understanding of the health of equipment in a highly automated fashion, and, provide reliability teams with the means to effectively assign condition and determine risk associated with critical equipment. These tools enable experts to focus their attention on analysis, and dramatically reduce their efforts on data mining. In this way, technology enables NSPI to optimize the use of experts and specialists to close the gap on demographic concerns.

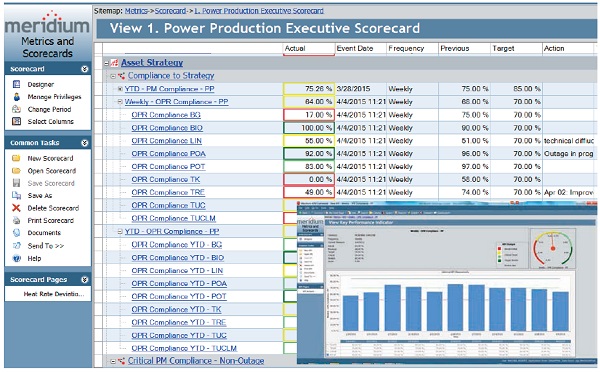

4) Information management. The roll-up and management of data from NSPI’s standardized reliability programmes is a story about ‘Big Data’. It is a major issue (and opportunity) recognized throughout industry. Previously, the Company struggled to ensure that all the deficiencies, recommendations and engineering actions were managed, assigned, and tracked. This created the potential for things to slip through the cracks; a situation which – from an organizational, customer and regulatory perspective – is not acceptable. NSPI has deployed tools to manage, integrate and synthesize all fleet equipment information to: produce measures, KPIs, Dashboards and Equipment Reports for internal and external consumption. This information layer is something that the company views as absolutely critical to comprehensive asset management and is best illustrated by NSPIs Management Scorecards. These (see Figure 3) are highly automated and common scorecards that are used at every Station to: specify key business measures and their targets, to track actual performance against those targets, and to enable identification of persistent issues. In addition to safety and environmental measures, the content incorporates performance, reliability, work management and financial measures. This level of data integration and syntheses is a direct result of the fleet wide processes and tools outlined in the Figure 1 pyramid.

5) Asset planning. Information gathered from the company’s asset management programme translates into the condition assessment and risk calculation, the Asset Management Mechanism outlined in Figure 2. In this way, asset planning is viewed as a risk mitigation exercise. Reliability teams examine the risk and mitigation tools available to the business, and apply the most effective solution to each major risk. This exercise is conducted across all major asset classes and the outcome includes short and long term investment plans, planned outage timing and scope, and maintenance strategy improvements. Multi-year investment and outage planning are essential to understand long term asset costs and this approach therefore delivers rigorous information into the generation planning effort. The result is that strategic business decisions regarding the sustaining or retiring of units, and the timing of new generation investment, are enhanced by the asset management programme.

DEPLOYMENT

NSPI’s asset management approach has been guided by two key concepts:

- Success in Asset Management is determined by how well the dozens of related processes (see Figure 1 Pyramid) are integrated at the operational level.

- Information systems success in gathering, integrating and synthesizing operational information is essential to measuring performance, sustaining asset management and enabling continuous improvement.

These guiding thoughts were central to NSPI’s approach throughout the design and implementation phases and remain a focus as NSPI sustains and improves its asset management programme. That is not to say that implementing such a comprehensive approach is easy. There are numerous technical hurdles to overcome and many business processes to engage and redesign – and change management is absolutely critical. With these principles and challenges in mind, NSPI applied a layered approach to asset management. The company’s five asset management layers (work management, reliability processes, advanced technologies, information management and asset planning), along with the key elements contained within each layer, compose the Asset Management Pyramid. Deployment of each layer (and many of the sub-elements) was made independently, but, considered the final interrelationships from a business process and information perspective. This low risk approach helped to minimize the organizational churn often associated with enterprise deployment efforts that have one major ‘turn-on’ date. In support of the asset management programme the company established an Asset Management Office (AMO) which was mandated to design, deploy and sustain the programme. While the AMO was an addition to the business, many of its functions centralized existing dispersed business activities such that there was an obvious net overall benefit to the organization.

DEPLOYMENT CHALLENGES

Based on NSPI’s experience, and consultation with numerous utilities, many challenges have been identified and should be anticipated when deploying fleet wide asset management programmes. Some of these challenges include:

- Work Management: Establishing work management standards and common planning practices is difficult. Individual plants will invariably exhibit ‘process drift’. The standards are necessary for adequately prescribing maintenance strategies, acquiring information from strategy execution and measuring programme compliance. NSPI adopted a Planning Team which meets regularly to review associated practices, refine measures to manage practice and provide education and support to individuals new to the programme.

- Maintenance Strategies. Typically designed at plant level, so standardization is difficult to initiate and sustain. Changes are typically made locally with a plant’s best interest in mind, but not necessarily with appropriate rigour and result. NSPI adopted Fleet Reliability Teams (and Process) to design maintenance strategies, engage stakeholders, and implement and sustain strategies. Measures are designed and implemented to ensure compliance is measured.

- PdM and NDT programmes. Are generally executed differently at different plants. The use of information systems that prescribe standards, acquire results and manage recommendations is an essential asset management function. NSPI’s approach included standardized service contracts, singular data systems and data integration to manage all associated information.

- Information technologies. Are a true enabler of an Enterprise Asset Management programme. However, navigating corporate IT standards and security is essential but difficult.

Comprehensive asset management requires the use of many information tools and technologies. Integration balances the right combination of business process knowledge, asset management vision and IT knowhow. It is common to get this mix wrong, the result being a lesser form of asset management. In short, the effort to design and deploy comprehensive asset management throughout a generating fleet is big and should not be underestimated, however, if done well the prize is huge.

NOVA SCOTIA POWER’S PARTNERS IN ASSET MANAGEMENT

NSPI has taken the tactical approach that it must partner with excellent providers to maintain such a broad sweeping asset management programme. Not all of the capabilities are present within the company as core business capabilities. As a result NSPI has developed some critical partnerships to support its programme. These partners were selected both on the quality of their products but equally importantly on their vision of asset management and their flexibility to grow with NSPI as it continues to improve its model. This has enabled NSPI personnel to focus on the core business activities while still developing, deploying and growing its AM model.

Areas of partnership include:

- CMMS: Directline (by Megamations)

- Maintenance Strategy Design: ACUREN and TG Advisors and Intertek

- PdM Programme Execution: ACUREN

- Advanced Pattern Recognition: PdP (by Scientech)

- Thermal Performance Monitoring System: PMAX (by Scientech)

- Maintenance Strategy Tools: Meridium APM (by Meridium)

- Mobile Technology: OPR (by Meridium)

- Metrics/Scorecards/Dashboards: Meridium APM

- Generation Equipment Reporting: Meridium APM

- Electronic Operator Logs: Meridium APM

- Data Historian: PI (by OSI)

- Turbine/Generator Health Assessment Data System: by TG Advisors

- High Energy Piping Data System: by ACUREN

- Boiler Condition Monitoring: by Intertek-AWARE

- LM6000 Engine Reliability Data: SPS ORAP

- Inventory Management: by Maximo

ABOUT THE AUTHOR AND NSP

Rob MacNeil is Senior Technical Advisor at Nova Scotia Power and responsible for the Generation Fleet Asset Management programme. NSP owns and operates over 2,500 MW of generation fuelled by a mix of renewable and fossil energy sources. The generating fleet includes twelve thermal, one tidal and fifty generating units, as well as seven combustion turbines, one combined cycle unit and a growing fleet of wind turbines.

Rob MacNeil is Senior Technical Advisor at Nova Scotia Power and responsible for the Generation Fleet Asset Management programme. NSP owns and operates over 2,500 MW of generation fuelled by a mix of renewable and fossil energy sources. The generating fleet includes twelve thermal, one tidal and fifty generating units, as well as seven combustion turbines, one combined cycle unit and a growing fleet of wind turbines.